A Mechanical Ventilation with Heat Recovery (MVHR) ventilation system is a technology that requires pre-design before it can be installed into a home, office, school or boat. The MVHR may include any and all of the following schedule of services:

-

Calculation of required boost airflow rate to meet or surpass Part F Building Regulations

-

Sizing and specification of the MVHR unit

-

2D ductwork layout

-

3D Plant room layout (advised, but not always crucial)

-

An assessment of potential structural conflicts with the ducting – and how this will be resolved – whether by notching a joist or cutting a steel (unlikely), or finding another route or boxing in. It’s a lot cheaper to do this on paper than on site…

-

Acoustic assessment based on both in-duct and at-valve air velocities

-

Pressure drop calculations

-

A full ventilation specification document

-

Installer Guidelines document (if installation will be completed by others)

-

Airing and plumbing schematics

It goes without saying that our company provides all of the above as part of its standard detailed MVHR design, but a lot of others will pick and choose what they offer as part of their design service – and it’s crucial you know what’s covered.

When should an MVHR ductwork design be started?

The MVHR design should be completed as early into the building design process as possible, ideally around the planning stage. This is so the unit location, risers for ducts and the movement of ducts around the building can be mitigated to take up as little space as possible.

A good MVHR design will take two to four weeks to complete, and require input from the architect or client on final valves locations in rooms, MVHR unit location and structural points.

The highest-quality MVHR units come from Europe, so the lead-in time for delivery to site can be up to four weeks – this is another factor to consider when including the MVHR installation in the build programme.

The location of the MVHR ductwork itself should be prioritised ahead of electrical wiring or plumbing layouts, because moving or diverting an air duct around a pipe or cable has a bigger impact on the duct’s pressure drop or resistance than moving a water pipe or cable, as it can affect acoustics and efficiency. Moving a pipe or cable around an MVHR duct costs nothing.

Doing the MVHR early also allows the designer to work out how much riser space they might need, as well as the plant room layout, external grille location and the necessity (or not) of lowered ceilings or reinforced stud walls to hide ducting.

What does a badly designed MVHR layout actually look like?

Our company spends a lot of time designing our MVHR systems to be as quiet, comfortable and energy efficient as possible. That’s why we charge what we do for detailed MVHR design layouts.

However, within the nascent UK MVHR industry, we are an outlier. There are lots of MVHR companies who will either sell the kit without any design, or who will complete a rough design that doesn’t take into account acoustics or pressure drops, either for a small fee or a fee hidden in the materials costs (ie, “free”). The problem with not doing a proper design is that it costs a lot more money to fix once on site – as steel beams and joists can’t be moved.

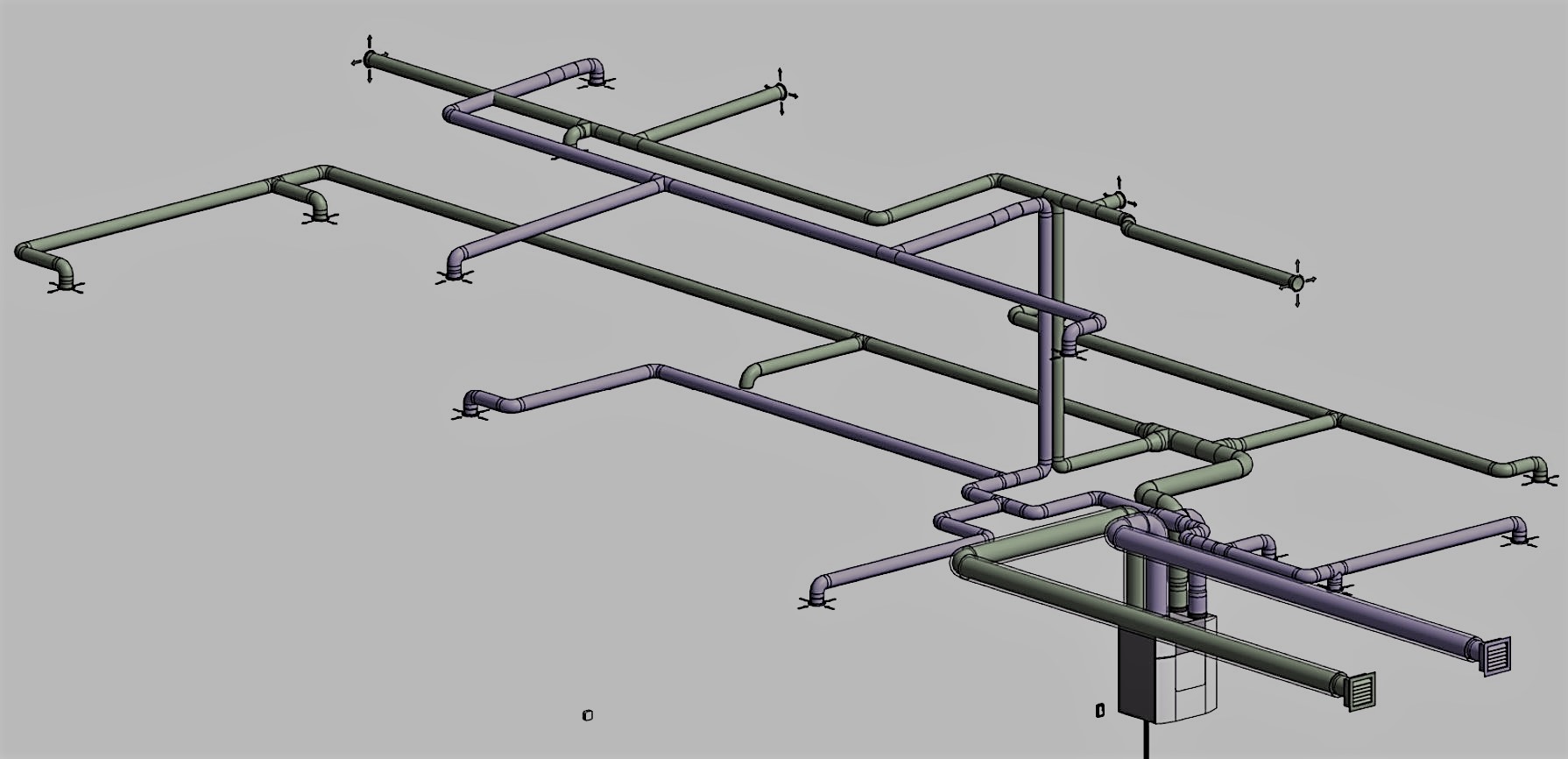

Without naming the offender, here’s a 3D MVHR design that a potential client submitted to me, completed by a large rival UK MVHR installer:

At a glance, this design looks really nice. But there are some key issues that will cause headaches for the client later on:

- There’s only sound attenuation around the unit (to prevent fan breakout noise). There’s no cross-talk sound attenuation to prevent noise travelling between rooms via the ducts

- The system hasn’t shown how it will deal with structural issues – 125mm diameter ducts run across the ceiling in all directions – does this mean the designer has assumed a 125mm lowered ceiling void across the entire property?

A cheap or free MVHR design will cost more in the long run

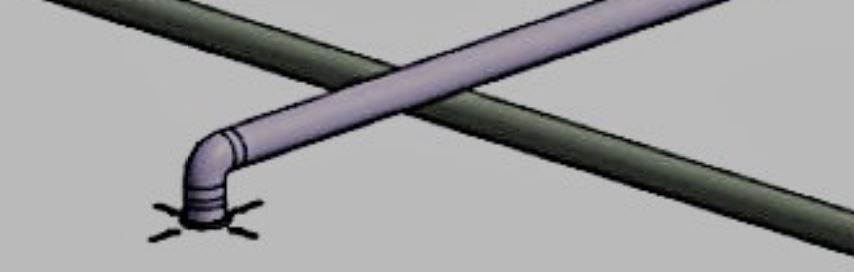

This MVHR design by a rival company doesn’t work at all. The ductwork crosses over in two very serious ways. In the first, the supply duct crosses above the extract duct, which would create a 250mm ceiling void height:

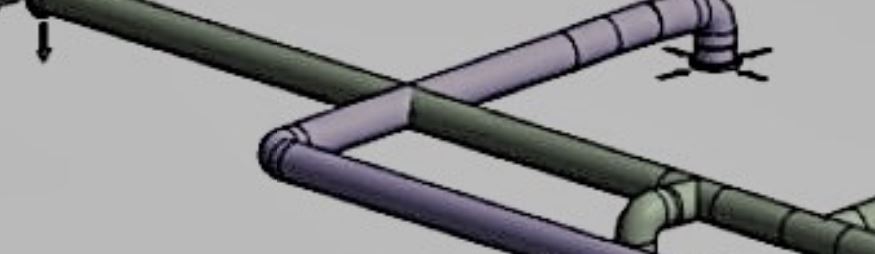

Even worse, at another point they have a supply and extract duct running through one another. This is of course possible in a digital format, but impossible in the real world:

What these two issues mean on site are extra costs and delays for the client, and potentially a loss of ceiling height where it wouldn’t have been necessary if the MVHR ductwork had been properly designed.

Either way, these are both terrible options for a client who may have spent money on a proper design process.

Detailed MVHR design is worth paying for…

Getting a detailed MVHR design done ahead of time saves time and money, and helps the installation on site run smoothly – preventing dependencies with other trades and keeping the build programme on time. If you’d like to find out how much it costs for a full detailed MVHR design layout, please contact me on patrick [@] heatspaceandlight.com.